|

Technology Development and Commercialization |  |

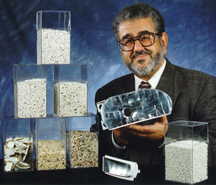

Process for Recovering Usable Plastics from Mixed Plastic WasteDiscover Awards Finalist!

Argonne researchers have developed and patented a process, called "froth flotation," that separates individual, high-purity plastics from waste streams containing a mixture of plastics. The technology has been used to separate such plastics as acrylonitrile-butadiene-styrene (ABS), high-impact polystyrene (HIPS), and polypropylene (PP) from other plastics – without using hazardous chemicals – during scrap shredding and metal recovery operations. So far, the technology has proven successful in recovering selected plastics from obsolete appliances, auto shredder residue, disassembled car parts, industrial scrap plastics, and consumer electronics – and its potential for separating plastics is extensive. The recovered polymers are compatible with virgin materials and can be used for such products as computers, office equipment, auto parts, telephones, and home appliances. The Argonne process has been applied to a plastics waste stream generated from shredding obsolete appliances. For this application, the plastics stream is fed through a granulator, then to a three-step separation process. In the first and second stages, the ABS and HIPS are separated from the other plastics in gravity separation tanks. In the third stage, froth flotation, the surfaces of the equal-density HIPS and ABS particles are modified by placing them in an aqueous mixture that has certain chemical properties so that the HIPS particles float and separate from the ABS particles, which sink. Both products are recovered, rinsed, and dried. BackgroundAbout 2.8 million tons of household appliances, 10 million automobiles, and many tons of other products containing mixed plastics are scrapped each year. Although the metals from these products (typically representing about 75% of the total weight) are recovered for reuse, the remaining nonmetallic material is lost – disposed of in landfills. Over the past 15 years, as the amount of metal used in automobiles, appliances, and other products decreased and the amount of plastics significantly increased, less of the scrap material could be recycled because no one could cost effectively separate the high-purity plastics from a waste stream of incompatible mixed plastics. If they cannot be separated completely, the plastics lose most of their value. Separating the high-purity plastics from the rest of the waste stream poses a challenge because many separation methods depend on material density. ABS and HIPS are similar in density and cannot be separated to a high enough purity or employ large quantities of organic solvents, which raise environmental concerns. Argonne's process is the only technology that has successfully produced recycled ABS with a purity greater than 99%. The process can safely reclaim about 700 pounds of high-purity ABS and 10. pounds of high-purity HIPS from each 1,000 pounds of appliance scrap. ImportanceThere was a time when the idea of recycling aluminum cans seemed far-fetched – the cost was too high and the benefits too small. These days, almost 65% of aluminum cans are recycled; the cans represent only 1% of the waste taken to landfills – and this number continues to fall as recycling increases. Plastics are gradually replacing metals as the main component in America's products. More plastic and less metal will mean more waste as these products become obsolete unless plastics are recycled as completely as metals are now. Recycling plastics waste into usable products offers an alternative to more expensive virgin plastics. In a single year, Argonne's process could recover more than 300 million pounds of high-value plastics for reuse, save 1. trillion Btu in energy, and avoid disposal costs of $20 to $40 per ton of residue. The estimated market values of the products that Argonne has recovered so far are $0.40 per pound for ABS, $0.20 per pound for HIPS, and $0.15 per pound for PP. The process can be applied to recover other plastics from waste streams in a variety of industries. Manufacturers will be able to buy and use the plastics recovered by means of the Argonne process for about 50% of the cost of virgin materials. Because of the high purity of the recovered products, the quality of consumer products will not be affected. The energy and disposal cost savings will also be passed on to consumers. Because the plastics will be recycled rather than placed in a landfill and because no organic solvents will be used in the recovery process, the public will enjoy a cleaner environment. Status of TechnologyThe technology was initially demonstrated in a batch-scale test to produce 600 pounds of high-purity ABS at an experimental test facility located at Argonne. The quality of the recovered ABS was greater than 99%. The recovered material met all the specifications of the recycle market. A continuous pilot-process with a design capacity of 1,000 pounds per hour was designed, built, and installed at the Appliance Recycling Center of America's Minnesota facility. The pilot plant was operated over a six-month period, recovering more than 20,000 pounds of ABS. The technology passed its first major manufacturing test in December 1998, and testing was completed in April 1999. A 100% recycled ABS recovered by means of Argonne's process was successfully used to produce injection-molded "backcans" for an automobile headlamp. Despite the complicated shape of the component, the results of the injection molding test were very successful – the part met the specifications of automobile manufacturers. Argonne's research was funded by the Department of Energy, Office of Energy Efficiency and Renewable Energy, Office of Industrial Technologies. For More InformationFor more information, contact ArgonneTechnology Development and Commercialization (800-627-2596, partners@anl.gov). |

| U.S. Department of Energy Office of Science | UChicago Argonne LLC |

| Privacy & Security Notice | Contact Us |